Vertical insert injection molding is an elegant solution which makes a very strong part. When you wrap metal or like materials in plastic, it gives tough and durable material which may last for a long time. Unlike the various other ways of molding this is a process that many people put their part/insert into device and then filled with plastic.

Vertical insert molding makes products more resilient and aesthetically pleasing, in the case that they are visible to a customer. This method also facilitates the construction of products in arbitrary shapes and designs which make it a right choice for most types.

As more companies require exact manufacturing, vertical insert molding will also become important in the future. Manufacturers prefer it to other molding methods because this technology is capable of maintaining high-precision and most precision throughout the time in process.

Through vertical insert molding, companies are able to produce purpose-built products. This enables them to produce bespoke products with high levels of accuracy, and they are therefore able to be more productive in producing product at speed while achieving higher efficiency/data quality.

Vertical insert molding is a type of injection molding process that can help your manufacturing to be more efficient and produce better products. This will allow companies to eliminate the various steps in production and save both time and money with this technology. This also guarantees that the products are strong and do not get damaged quickly.

Used in vertical insert molding allows companies to have a product with increased durability over time and more resistance... This secures the insert in place to ensure a strong final product. Along with using a wide array of materials and finishes that allow products to resist water, chemicals, or other environmental conditions.

When it comes to manufacturing vertical insert molding offers several advantages. As a result, this can tailor fantastic products with accuracy and speed and reduce production costs. This also longens the life of products and hence they need less maintenance.

Our teams committed to providing superior customer service and vertical insert molding. Our dedicated teams always available for immediate and personalized supports. If it's maintenance troubleshooting or other issues we actively cooperate with our clients to quickly address any issues they confront. Our butler services method ensures that clients receive continuous assistance and support to builds long-lasting relationship based on trust and reliability.

Our solutions are based upon customer requirements. We incorporate cutting-edge technology. We vertical insert molding and trends in the industry of injection molding machines. By sourcing and integrating cutting edge components and features we boost the performance and effectiveness of our machines. Our commitment to continual support after sale ensures that we will be able to improve our solutions throughout their life cycle.

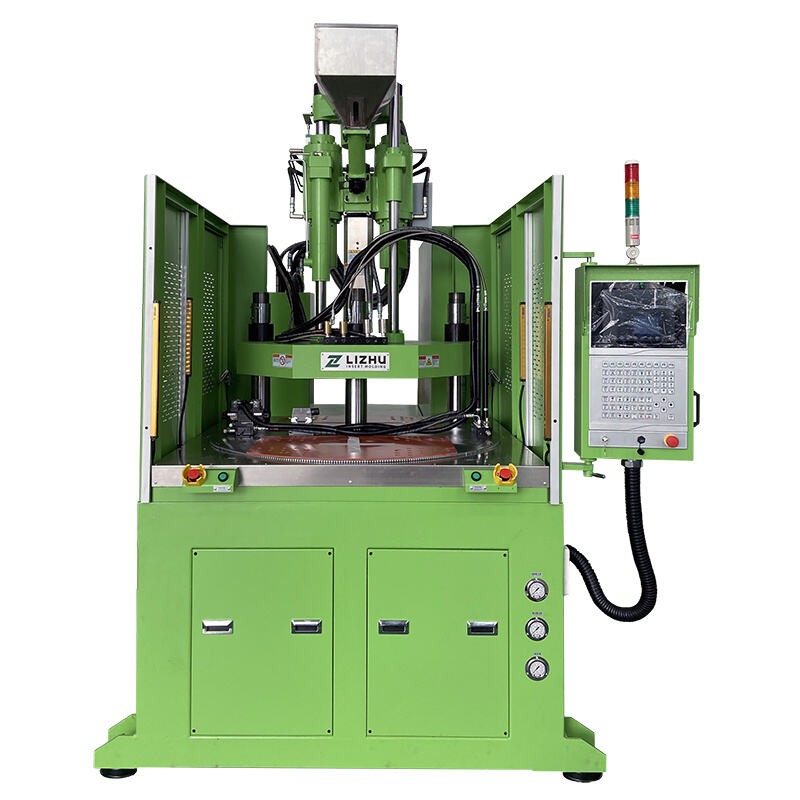

Our customers appreciate the deep customization we provide. We realize that each project is unique which is why we provide a custom single-stop solution that is vertical insert molding. From the initial idea to the final implementation We work closely with our customers making sure the vision they have in mind is achieved. We currently have various models of standard machines sliding table machines multi-color machines and rotary machines up to 2000 tons. They are widely used in electronics telecommunications and aerospace industries as well as in home appliances everyday necessities, automotive, semiconductor packaging and medical. Our ability to execute turnkey projects assures a seamless and efficient service for our customers.

We have vertical insert molding in the injection molding machine industry. This has provided us with the knowledge and expertise. Additionally, we have a 20,000 square meter research and development centre. Our team consists of highly skilled professionals that are proficient in latest practices in the industry and technological advancements. LIZHU Machinery, through continuous technological innovation and advancement has been awarded over 100 patents including inventions and utility models that have established it as an advanced national company. Our products are at international high levels and have been recognized by TUV, CE, UL, and ISO 9001.