About Vertical Insert Molding Process -plement a wellprepared insert into the mold cavity Thermoplastic material of a particular type is then poured into this mould, resulting in the fabricated product as you see it. Compared to the space-consuming horizontal insert molding machines, vertical takes up a much smaller floor scale but they are not suitable for manufacturing bigger parts of material.

Vertical Insert Molding Machines to manufacture the products in bulk are essential. These are found at high processing speeds and standard quality in the manufacture process. Furthermore, this approach results in generating less waste and significantly reduces the hours of manual labor.

Vertical insert molding machines are capable of achieving an astoundingly high level of precision with regards to the manufacturing process. This method allows the inserts to be placed vertically into the mold that prevents any possibility of parting lines, which may lead to misalignment of an insert. Also, the molding machine is able to apply pressure onto an inserted material so that it fits securely with the thermoplastic resin.

Furthermore, the ability to include inserts directly in mold cavities also allows for producing complex parts containing features like channels or wiring running through them. It is particularly useful in industries such as electronics and medical devices, where individual element placement can be critical to the final device working properly.

As you can see, there have been advancements in vertical insert molding that has brought many new novel features to improve productivity and accuracy within the manufacturing process. The robotic aspects of these developments involved the use a robot to do automated insert loading and unloading, which according to Stackpole officials can result in cost savings as well as maintenance of quality parts.

Machines with optical sensors can automatically detect the presence of inserts in a mold, giving real-time feedback to control the production process on check location and orientation. In addition, the use of advanced software enables complex design with accurate geometries and unique aesthetics.

The addition of upside down insert molding makers has actually tremendously simplified production functions in different sectors. Manufacturers will likely continue to innovate in order not only to meet rising demand, but also as a way of maintaining quality standards.

Going forward, vertical insert molding machines might further integrate AI and machine learning technology for advanced functionalities. This capability could in turn allow molders to monitor and adjust the molding process more closely - on-line rather than at a library of historical information, helping create an even greater level of effectiveness manufacturing.

A host of factors must be considered in the selection of a vertical insert molding machine to help ensure that it will satisfy your needs. 1: Considering the types and sizes of goods that you will be producing, including what type of inserts must fit inside. This evaluation will adapt for the size and capacity of molding machine are required.

This also depends on the required degree of accuracy, use case materials utilized and needed volume capacity along with desired level of automation. You may also want to consider the post-sale support from the manufacturer in order for your machine last longer and stay productive over time.

ConclusionThe use of vertical insert molding machines provides several advantages for manufacturers in terms of precision, efficiency and automation. The growing need for high quality, low-cost manufacturing processes has furthered the progression within this evolving industry. Review your requirements and choose the machine that fits it; By doing this, you can improve all of these production processes and thus ensure a higher quality in the manufacture of its products.

Our team is committed providing superior customer services and vertical insert molding machine. Our team of professionals can be reached 24/7 to provide prompt personal assistance. When comes to troubleshooting maintenance or any other issues we are constantly working with clients to quickly address any issues they encounters. Our butler services method ensures that clients receives continuous assistance and supports in establishing lasting partnership based trust and reliability.

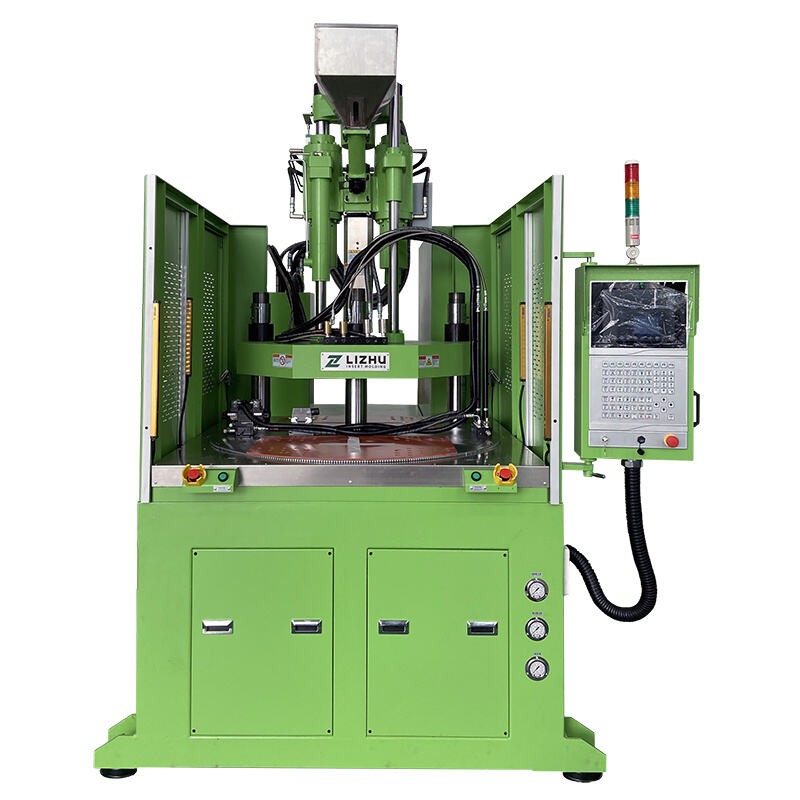

With more than 33 years of experience in the field of injection molding machines We have amassed a wealth of understanding and vertical insert molding machine. We also have a huge 20,000 square-meter research and design center. Our team is comprised of highly skilled professionals who are knowledgeable of the latest technological advances and best practices in the field. With continuous technological innovation, LIZHU Machinery has obtained more than 100 patents on designs and utility models, creating itself as a nationwide high-tech business. Our products have reached international advanced levels, and have been certified by TUV CE UL and ISO 9001.

We excel at providing extensive customization options for our customers. We understand that every project is unique therefore we vertical insert molding machine that is tailored to each client's individual requirements. We are in close contact with clients from the initial concept to the last implementation. We ensure that the vision becomes a reality. We offer a wide range of models including sliding table machines as well as rotating machines. Multi-color machines are accessible up to 2000 tons. These machines are commonly used in the field of telecommunications electronics aerospace, automotive, medical appliance, home appliances and daily needs and packaging for semiconductors. Our ability to manage turnkey projects guarantees a smooth and efficient service for our customers.

Our vertical insert molding machine. We incorporate cutting-edge technology. We stay up-to-date with the most current innovations and trends within the field of injection molding machines. By sourcing and integrating cutting-edge components and features we improve the efficiency and performance of our machines. In addition our commitment to a continual after-sales service guarantees that our products remain optimized throughout their lifecycle.